Russ V

If you are going to do a couple of rosettes only, hot

glue is the way. If you are going to do a lot of the same size you can

build a table for them. I built a second table that I double tape to the

original table. My original table I never use directly. I drilled a

1/4" hole in the center and make a secondary table that I attach with

double sided tape. This hole helps me quickly align my rotary table to the

router and to align the second table to the first table by using a 1/4"

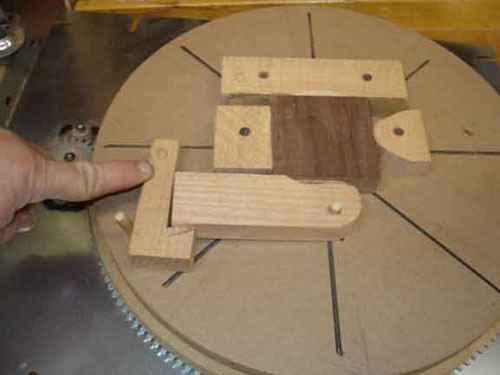

dowel. To make the rosette hold down table I screwed blocks on three sides

of center to hold the rosette centered. The 4th side is on a pivot that

when closed I lock it with the 5th swivel block and a dowel pin to hold it

locked. If you are going to cut on the outside

to make it round then use a small piece of DS tape to hold the piece once you

cut it loose. If they are already cut to size and shape the you only need

to lock it in the table. I used sand paper on the stationary blocks and a

nail cut off on the pivot block to help hold the rosette. I am

thinking that now I am going to make a table with sliding track going out in 4

directions from center so I can then adjust the blocks to fit any size rosette.

I wouldn't particularly want to use the indexing table

to cut blocks round. On small objects I use the band saw and then a jig on

my oscillating sander to smooth the edges and get the final diameter. Much

Much Safer. Use the rotary table to cut the surface only not all the way

thru. Screws, hot glue, DS tape are all good and well, but when I do

rosettes I usually do 100 or 200 at a time. The less screwing the better (

in this case). With my table, I can change out the rosette in seconds . .

. no holes, no hot glue residue to clean up, and no DS tape to peel.

Again, I think I will redo this table with sliding tracks, I then can set

up to do any size rosette ( or box lid). The DS tape to hold the secondary

table isn't holding much (stress wise) since I use a dowel in the center.

The tape only hold the table from spinning. I guess I could screw

the

secondary table down but I like to keep my primary table clean with only

the center hole so it will last. I think I am going to put a Formica

laminate on it to make it more durable and let DS tape stick better.

The center hole technique to center everything is really handy. Once I

center the table, everything can be centered quicker too. For

example, If I am going to center several object of the same size, I make one

with a hole in the center so I can then set it in place with a dowel. Then

I DS tape cleats in place on two sides. Now, every piece I set, whether

with hot glue, DS tape or whatever, the cleats will help me align to center

quicker.

Russv

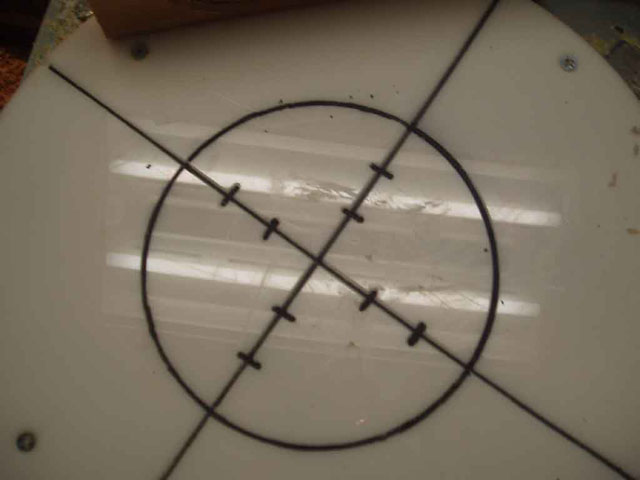

As to centering, if you look at my table pics you will see

there are lines drawn on the table. To create lines is as follows:

After centering the machine, put a bit with a point in the router. Put the

router over center, lock the carriage down on the x axis, and plunge down

to barely touch the table. Start the router and plunge down. Then

slide the router along the y axis in one direction to the outside edge to make a

score line. Come back to center. Do not go the other direction on

the y axis. Turn the handle on the rotary table one full turn and slide

the router along the y axis again and back to center. Do this 8 times and

you

should see 4 long lines on your table at 45 degrees apart. The reason you

don't go both directions off the y axis is so that now when you look at the

lines, they should look straight all along the line even though you drew it by

two operations. If the lines don't look straight, then you weren't

centered.

If everything looks straight, then you are good to go. Make sure you

always line the router to this center point and you will be good to go. To align

a block of wood is simple now. If the block of wood has 90 degree corners

then when you line up all 4 corners on the lines on your table you are centered.

This still works on an octagon shape also. make sure you use a pen in your

score lines to make them easier to see.

Curt George

John Doe

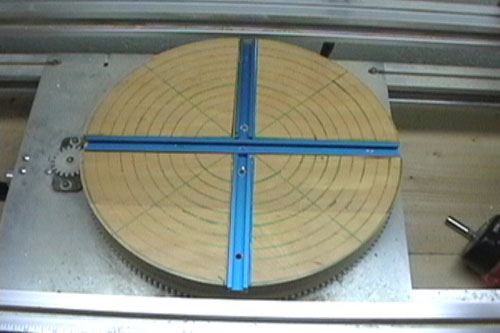

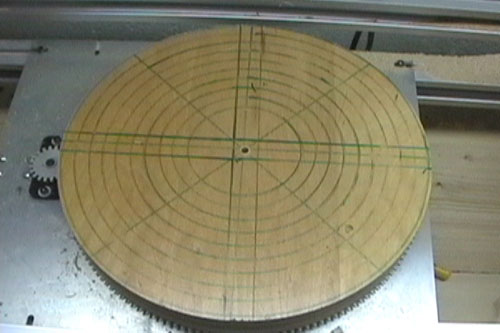

Here is what I did. I took a 14" square piece of drafting

table top, found center. Used a bowl cutting

template to draw 1" incremental circles. Then I routed a groove and

inserted T track to intersect in center using hold downs to hold sides of

material. Here's my problem, I am using a plunge cutting round over bit to round

over the outside edges and regardless of how tight I tighten it down it still

vibrates loose. I don't think I'm taking too big a bite each pass. What are some

good projects for the rotary table?

To keep things in place use a piece of sticky

back sand paper about 100 grit or so. Or even some stair step non-skid

tape. It will cure your slip problem. The drafting table top is just

too slick.

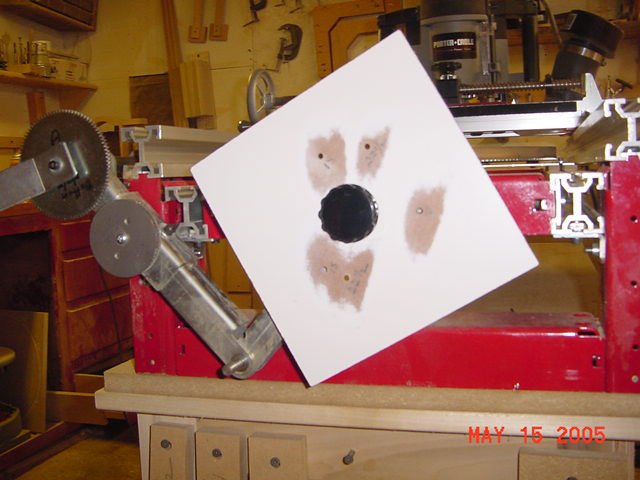

First I am from Bloomington Il. I have been learning from everybody on this forum. The first picture is the way I hooked up the table to my head stock. I use different tables for each thing I do on the table. I just use 1/4" pins to line everything up. The second picture shows that I am making new indexing plates. This one is for 15 degree and 22 1/2 degree spacing. They are made out of 1/8" hard board. The next two pictures are of the way I hold down my rosettes. In the bottom there is a screw through the plywood with just a small tip through to pin the rosette when I lock the arm in. I would like say that I really enjoy this forum and wish that we could all meet sometime. I have been woodworking for about 20 years as a second income. I work for (now don't laugh) The Town Of Normal, Illinois. My hours are am-12pm Tuesday thru Friday so this gives me time to do my woodworking. For the last 6 years I have been doing a lot of kitchens and am tired of doing them. So with my Legacy I am trying something different. OK enough rambling time to relax.